Paper Cup Forming Machine

Product Video

Specification

| Paper size | 4-16oz (mold exchangeable) or customize |

| Paper Material | 140-350 gsm One-side or two side PE (polyethylene) film coated paper |

| Production speed | 60-80 pieces/ minute |

| Power Source | 220V50Hz1phase/380V50Hz3phase |

| Total Power | 7KW |

| Total Weight | 3000KG |

| Dimension | 2800*1400*1850mm |

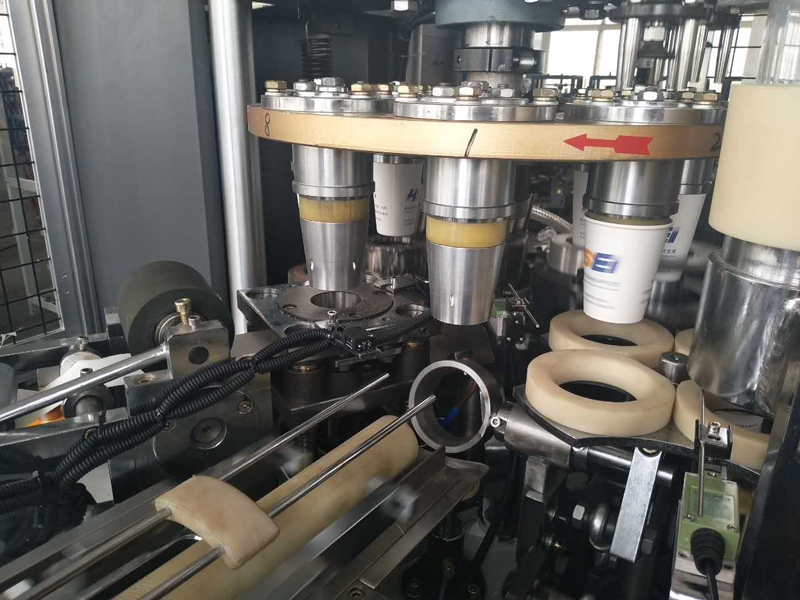

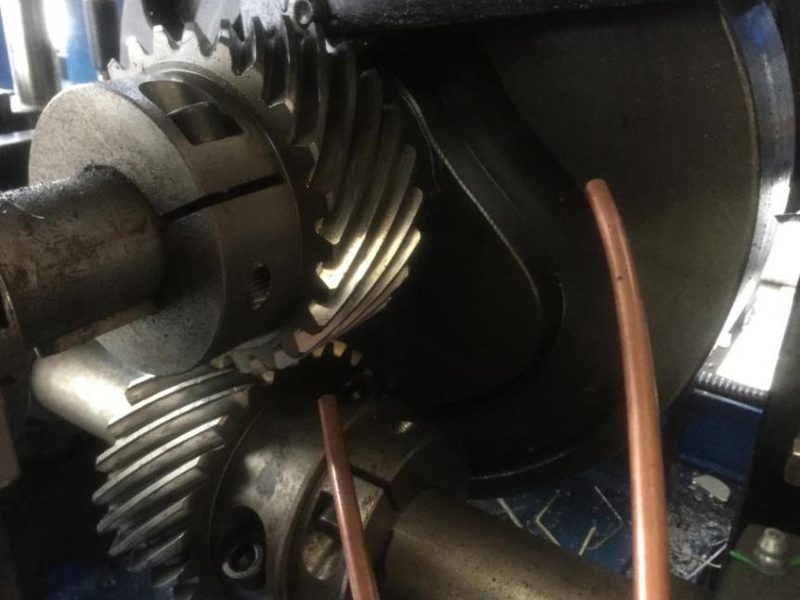

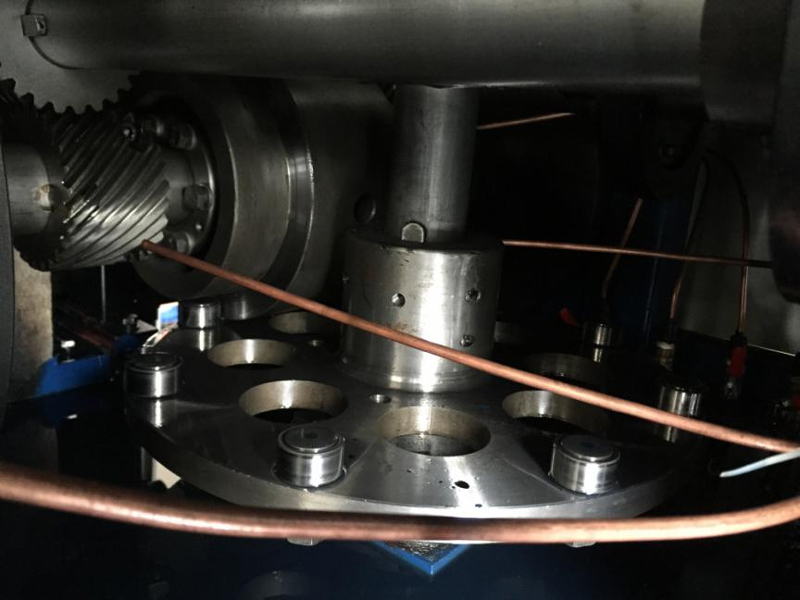

Machine Detailed Picture

1. Ultrasonic do sealing. Good for full printing or double PE coated paper material produce.

2. With single plate,advantage: no bottom paper upside down.

3. For transmission, this paper cup machine makes use of high quality open type cams and gearwheels, instead of chains and gearboxes.

4. Automatic lubrication system ensuring machine 24 hours non-stop running

5. Bottom paper punching uses stretch blade, the advantage: evenly wrinkle, no leakage, long life span and change mould easily, reduce the damage of the machine.

6. Use heating equipment for cup bottom heating,ensuring sufficient heating and contributing the zero leakage of drinks cups.

7. with safe guard, more nice and safe condition Flat operation table makes no waste paper drop in the machine.

8. With high level and easy operation finish cup auto collecting equipment